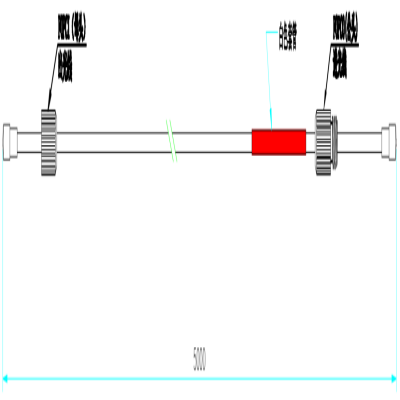

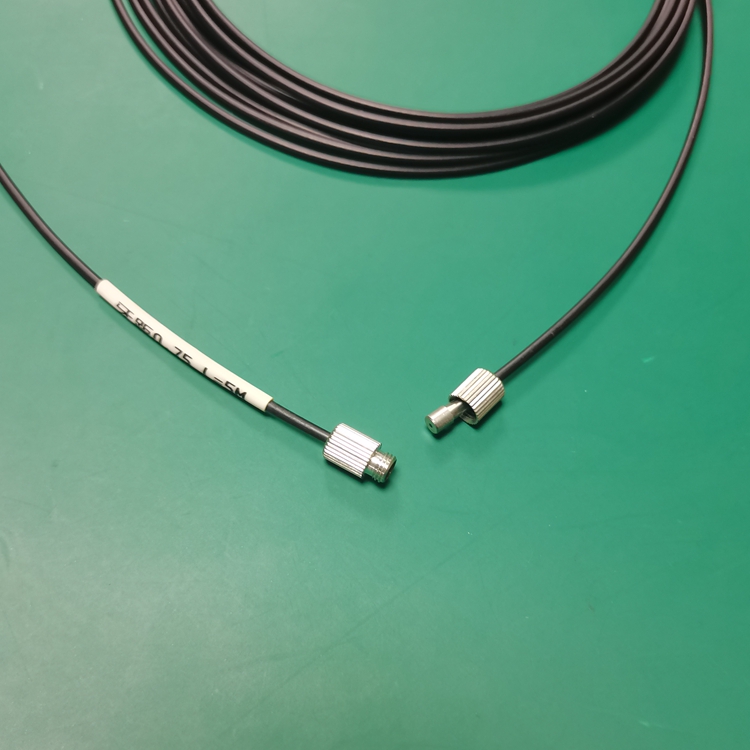

The 1-meter aviation loopback communication cable fiber optic patch cord is a 1-meter optical communication passive device designed specifically for aerospace scenarios. It forms a looped closed loop through the optical fiber core wire, and is equipped with aviation-grade optical connectors at both ends to achieve self-loop transmission and testing of optical signals. The product must meet the strict requirements of the aviation field for high temperature resistance, vibration resistance, and electromagnetic interference prevention. It is often used for on-site debugging, system self-test, and short-distance closed-loop communication of airborne electronic equipment. It has the characteristics of lightweight, high reliability, and strong environmental adaptability.

Product Overview

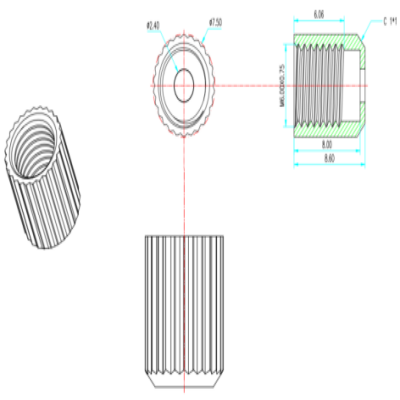

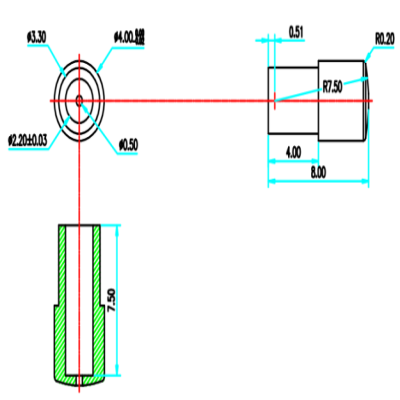

This fiber optic loopback patch cord (also known as a loopback plug) is a precision test tool designed specifically for avionics and high-reliability communications. It features a high-quality, durable plastic housing with integrated precision end-face connectors. Its sophisticated optical path design enables seamless, low-loss loopback of output optical signals back to the input port, making it an essential tool for equipment self-diagnosis, fault diagnosis, port testing, and maintenance.

Core Functions and Applications

Equipment Self-diagnosis and Diagnosis: Quickly checks the functioning of fiber optic ports on aircraft communication systems, network switches, servers, routers, and other equipment. By simulating a link connection, it helps ground crew and engineers quickly identify equipment faults or external fiber link issues.

Port Performance Testing: Verifies the transmit and receive functionality of optical modules (SFP, SFP+, etc.) and is a critical step in regular maintenance, installation, and commissioning of aviation equipment.

Network Troubleshooting: In complex aviation communication networks, segmented loopback testing allows for efficient isolation and localization of faults, significantly reducing maintenance time and ensuring flight punctuality. System Burn-in and Debugging: During system integration and extended operational testing, this feature provides stable loopback connections for optical ports, ensuring continuity and reliability during the testing process.

Typical Application Scenarios

Ground maintenance of aircraft inflight communications and entertainment (IFEC) systems

Maintenance of data communications equipment (switches, routers) in airport terminals

Production testing and quality inspection for avionics manufacturers

Periodic maintenance and troubleshooting in aircraft maintenance repair (MRO) facilities