Fiber optic woven luminous mesh is a mesh structure made of flexible optical fiber (usually plastic optical fiber POF or side-emitting optical fiber) through textile technology (such as knitting, weaving, crocheting, etc.), combined with LED light source or laser light guide technology to achieve uniform, dynamic or programmable luminous effects. It is both decorative and functional, and is widely used in architectural landscape, stage art, fashion design and intelligent interaction fields.

Product Description:

Add a dreamy glow to your holiday! Our fiber optic net lights utilize a unique weaving process to create a soft, durable, and evenly illuminated woven net.

It's more than just a string of lights; it's a technologically advanced fiber optic fabric. The core is meticulously woven from countless fine fiber optic strands. The light source is centrally located in a secure location, transmitting light through the strands to create a soft, non-glaring, all-over glow, creating a romantic and mysterious holiday atmosphere.

Features:

Uniform Illumination: The entire net emits a soft, even glow, without the harshness of traditional LEDs, for a more visually appealing experience.

Safe and Reliable: Fiber optics generate no heat or conduct electricity, making them ideal for homes with children and pets, and suitable for outdoor use in rain or shine.

Energy-Saving and Eco-Friendly: A single low-power LED light source illuminates the entire net, saving more energy than traditional light strings.

Easy to Use: Typically powered by USB, simply connect to a power bank. The net is lightweight and flexible, making it easy to wrap, hang, or drape.

Easy Storage: Folds for storage, resists tangling, and is durable.

Main Applications:

Christmas Tree Decorations: Wrap directly around your Christmas tree to instantly create a one-of-a-kind, all-luminous magical tree.

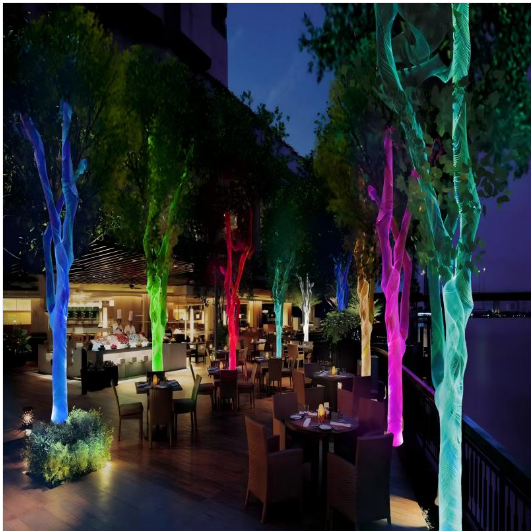

Holiday Atmosphere: Suitable for Halloween, New Year's, weddings, parties, and more. Hang from walls, ceilings, or windows to easily create a dreamy scene.

Commercial Displays: An excellent eye-catching decorative material for shopping malls, hotels, cafes, and window displays.

Outdoor Gardens: Decorate your garden's shrubs, trees, or fences to imbue your garden with a magical nighttime atmosphere.