Are you looking for a reliable, high-performance replacement fiber for your Epicare LPX or other Alexandrite laser systems? Our laser hair removal fiber is the ideal choice. Designed as a direct replacement component, it meets the high standards of professional medical aesthetic equipment.

This product uses high-quality fiber at its core, offering a variety of core diameter options from 1000um to 2000um to ensure perfect compatibility with your device and stable laser energy transmission. This means you can not only quickly restore your device to normal operation but also guarantee peak performance and absolute safety for every hair removal treatment.

Product Overview

This replacement fiber for laser hair removal devices is an original, direct replacement part designed specifically for the Epicare LPX and similar Alexandrite laser systems. We understand the importance of a reliable fiber for your clinical practice, and therefore rigorously control every step from materials to finished product. The product offers core diameter options from 1000um to 2000um, designed to perfectly match your device parameters. This not only allows your device to quickly return to optimal working condition but also ensures excellent results and operational safety for every treatment. It is an essential, cost-effective consumable for clinics and beauty salons.

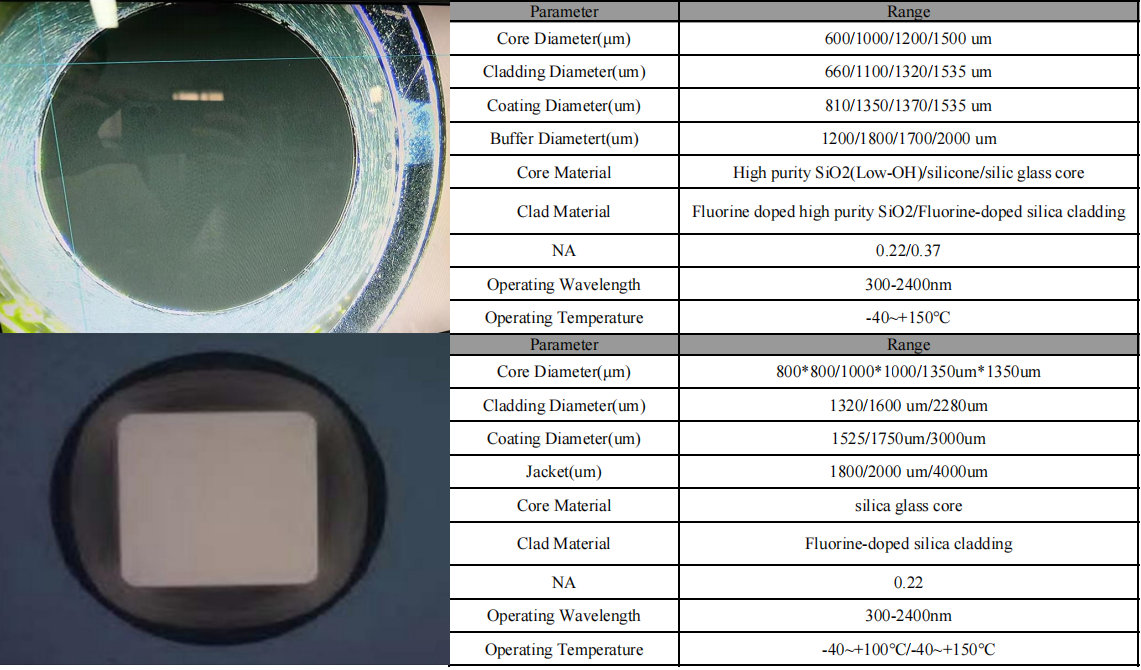

Core Specifications

| Parameter Item | Specification Details |

| Product Type | Replacement Fiber for Laser Devices |

| Compatible Brands | Epicare LPX, Alexandrite Laser Systems |

| Core Diameter | 1000um, 1200um, 1500um, 2000um (Optional) |

| Fiber Material | High-purity quartz glass |

| Coating Material | High-quality polymer |

| Interface Type | Standard metal interface (consistent with original specifications) |

| Application Areas | Professional laser hair removal, medical aesthetics |

Product Core Advantages Explained

Precise Compatibility, Perfect Match

This product has undergone rigorous testing to ensure perfect physical interface and optical performance compatibility with Epicare LPX laser systems and most devices using Alexandrite laser technology, avoiding equipment malfunctions or performance losses due to incompatible accessories.

Superior Transmission, Excellent Performance

Using high-purity quartz glass fiber, it has an extremely low energy attenuation rate and an excellent laser damage threshold. It can stably and efficiently transmit laser energy, directly affecting the final effect and operational efficiency of hair removal treatment, ensuring that every joule of energy is precisely applied to the target tissue.

Robust and Durable, Safe and Secure

A superior polymer coating and robust metal connectors give the optical fiber excellent flexibility, abrasion resistance, and tensile strength. This not only extends the product's lifespan and reduces your long-term operating costs, but also provides crucial protection for treatment safety and stable equipment operation.

Plug and Play, Convenient and Hassle-Free

As a direct replacement, installation is simple and quick. You can replace it quickly without complex calibration or debugging, greatly reducing equipment downtime and making your business operations smoother and more efficient.

5. Why Choose Us?

Specialized Focus: We specialize in medical laser accessories and deeply understand the stringent requirements of professional equipment.

Quality Assurance: Every fiber undergoes rigorous quality testing before leaving the factory to ensure reliable performance.

Professional Support: We provide professional technical consultation and after-sales service to ensure your peace of mind.

Rapid Response: We understand the importance of time to your business and therefore promise fast order processing and delivery.

6. Frequently Asked Questions

Q: How do I confirm if this optical fiber is compatible with my Epicare LPX device?

A: This fiber optic cable is a direct replacement model designed specifically for Epicare LPX. Please provide the specific model number of your device, and our customer service staff will confirm 100% compatibility for you.

Q: What is the warranty period?

A: We offer a 12-month warranty on this product, stemming from our absolute confidence in its quality.

Q: How should I choose the core diameter of the fiber optic cable?

A: Different diameters affect spot size and energy density. Generally, thinner fibers (e.g., 1000um) are more suitable for delicate areas; thicker fibers (e.g., 2000um) are suitable for rapidly treating large areas. You can refer to the original equipment manufacturer's recommendations or choose based on clinical experience.

Don't let a simple accessory disrupt your valuable clinical work. Order this high-performance Epicare LPX replacement fiber optic cable today to revitalize your equipment and ensure your clients always receive the best treatment experience. Click to contact us now for a quote.