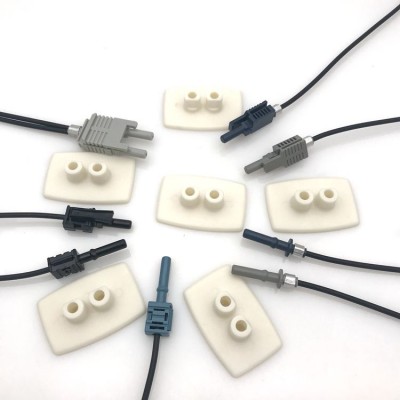

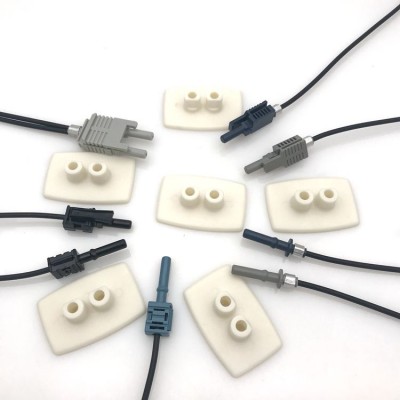

The HFBR-4593Z polishing fixture is a professional-grade fiber optic connector end-face preparation tool designed for precision polishing of SMA/LC/SC fiber optic interfaces. This product utilizes a high-precision polishing process to ensure ultra-low fiber end-face roughness (≤0.1μm), effectively reducing signal loss and improving fiber transmission stability.

1. Product Features

(1) Precision grinding design

Optimized end face flatness: ensures that the end face of the optical fiber reaches low insertion loss and high return loss after grinding

Adjustable pressure control: uniform pressure is applied to avoid damage to the optical fiber caused by excessive grinding.

(2) Structural design

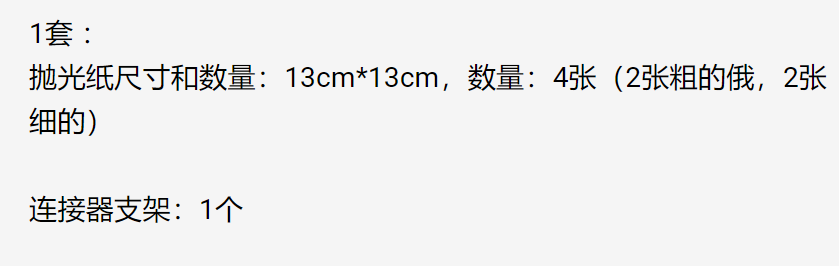

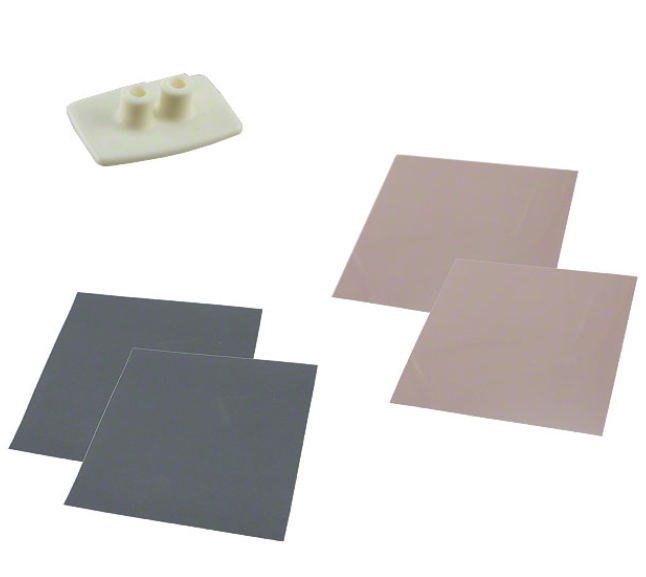

Modular assembly: can be ground in stages with different grinding papers

(3) Durability

High hardness material: the fixture body is made of wear-resistant engineering plastic/metal, which will not deform after long-term use.

Replaceable parts: grinding pads, fixing clamps and other vulnerable parts can be replaced separately

2. Main functions

(1) Improve the quality of the optical fiber end face

Through multi-stage grinding, eliminate end face burrs and scratches caused by cutting or crimping, making the optical signal transmission more stable.

(2) Reduce optical signal loss

Reduce insertion loss: The flat end face reduces light scattering and improves transmission efficiency

(3) Extend the life of the connector

The end face after grinding is more wear-resistant, reducing the impact of pollution or aging during long-term use.

3. Typical application scenarios

(1) Industrial communications: POF connector maintenance for PLC and sensor networks.

(2) Medical equipment: endoscopes, monitors, and other scenarios that require high-reliability fiber end faces.

(3) Automotive electronics: POF link optimization for vehicle-mounted MOST bus or LiDAR systems.

(4) Laboratory testing: end face standardization for studying POF transmission performance.