It is a cable specially designed and manufactured to connect the components in the Mitsubishi servo system according to the specific requirements of the Mitsubishi servo system and the personalized needs of users.

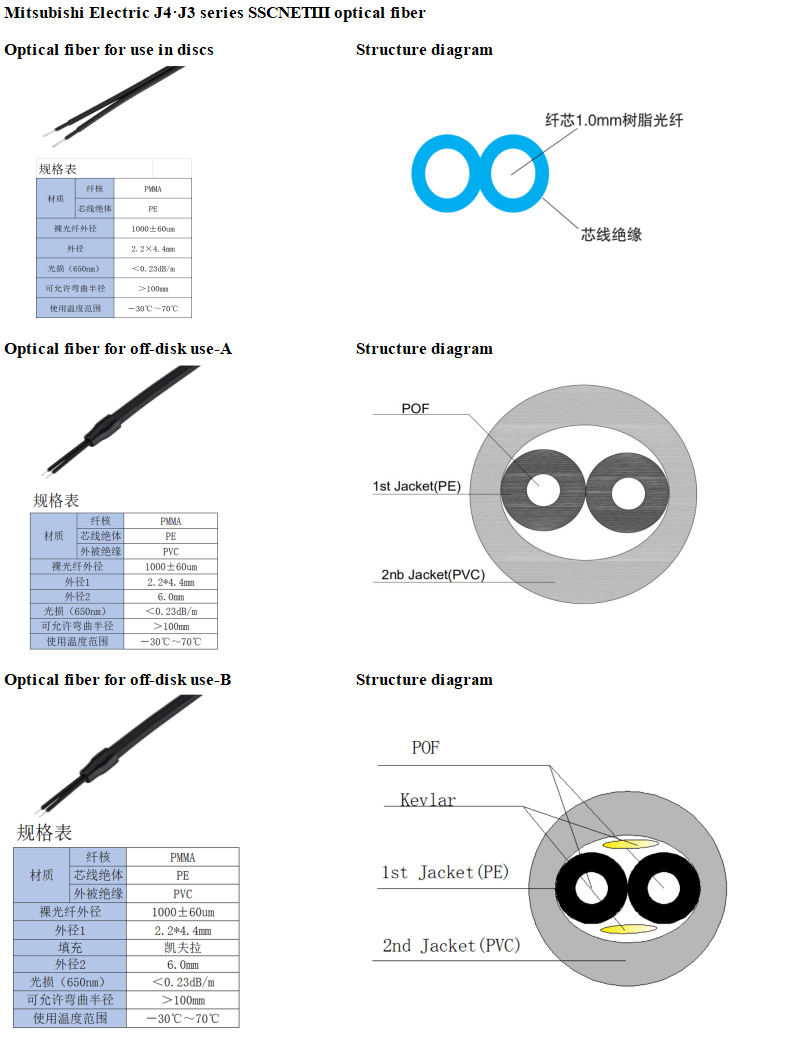

model:1.0*2.2*4.4mm,1.0*2.2*4.4*6.0mm,1.0*2.2*4.4*6.0mm with Kevlar

The MR-J3BUS03M-B is a high-performance, dual-core POF fiber optic cable specifically developed for Mitsubishi servo systems. It utilizes a side-by-side plastic optical fiber structure, ensuring 150Mbps high-speed transmission. It comes standard with an industrial-grade SC-J4BUS M-A interface, fully compatible with the full range of MR-J3/J4 servo drives.

Core Advantages:

✓ Military-grade anti-interference: >90dB EMI shielding effectiveness ensures zero signal distortion

✓ Superior adaptability: IP67 protection with PUR outer sheath, oil and corrosion resistant

✓ Space-optimized: 30mm industry-smallest bend radius, ensuring trouble-free robot arm installation

✓ Extreme environmental stability: Operating over a wide temperature range of -20°C to 75°C

Technical Highlights:

• Transmission Performance: Ultra-low signal attenuation <0.5dB/m

• Structural Design: 3.5mm dual-core POF fiber, flex lifespan >1 million cycles

• Connection Reliability: Gold-plated contacts, mating and unmating cycles >5000

Typical Applications:

▶ High-end five-axis CNC machine tool linkage system

▶ Six-axis industrial robot joint control

▶ High-precision positioning for intelligent production lines

▶ Synchronous motion control for packaging equipment

Quality Guarantee:

Original process standards, CE/RoHS dual certification, and successful application in leading projects such as Tesla and FANUC.