Small laser welding machines usually use pulsed or low-power continuous fiber lasers, which have high requirements on the flexibility, energy transmission efficiency and damage resistance of optical fibers. The energy fiber products provided by KINZ can meet this demand well. In addition, the energy fiber products provided by KINZ are rich in variety and excellent in performance, which can meet the diverse needs of different fields and different customers.

Structural composition

1. Fiber core: usually made of low OH quartz material, it is the transmission channel of optical signals. High-purity quartz material can ensure that light has low loss when it is transmitted in it, and can effectively reduce the attenuation of laser energy.

2. Cladding: generally made of fluorine-doped quartz material, its refractive index is lower than that of the core, which can limit the light to be transmitted in the core, realize total reflection of light, and thus ensure that the laser energy propagates along the axial direction of the optical fiber.

3. Coating layer: mostly acrylic resin material, the main function is to protect the core and cladding, enhance the mechanical strength of the optical fiber, and prevent the optical fiber from being affected by external mechanical stress, wear, etc.

Performance advantages:

1. Strong resistance to optical damage: can withstand higher laser power, not easy to cause optical damage due to excessive laser energy, and ensure the stability and service life of the optical fiber during laser welding.

2. High mechanical strength: quartz optical fiber has high mechanical strength, good resistance to atmospheric erosion, and no electromagnetic leakage during transmission. It is not affected by external electromagnetic radiation and can work stably in a more complex industrial environment.

Application scenario: Mainly used in small laser welding machines to transmit laser energy, transmit laser from the laser to the welding part, and realize welding of metal or other materials. Because of its good flexibility and high energy transmission efficiency, it can be flexibly arranged in the welding equipment, which is convenient for operation and use.

When buying fiber optic products, please look for our KINZ company. After years of focusing on the research and development and production of optical fiber, our full range of products, from quartz energy fiber to fluorescent special fiber, from standard connectors to customized cable assemblies, have undergone rigorous testing to ensure that the transmission loss, damage threshold and mechanical strength of each meter of optical fiber far exceed industry standards.

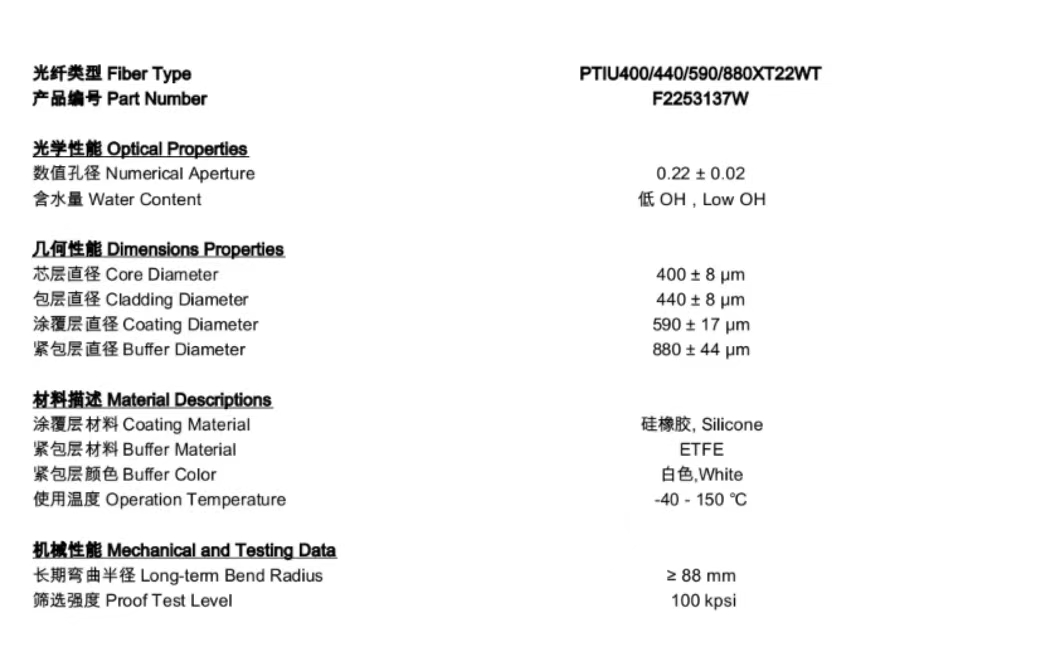

Product Specifications