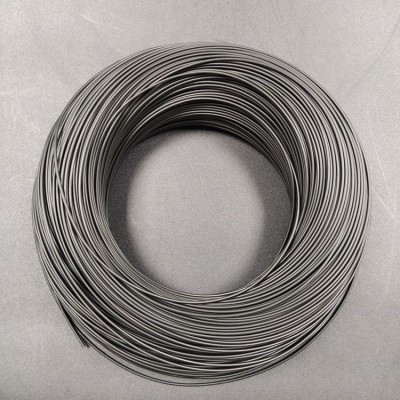

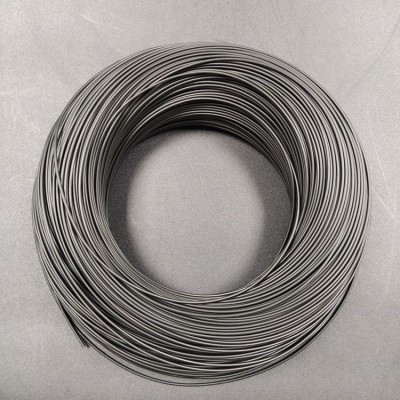

This product is a standard 1.0/2.2mm plastic optical fiber sensor cable. It utilizes a high-purity PMMA core and a specialized sheath design, offering a low transmission loss of 0.18dB/m and precise concentricity of ±0.5mm. Compatible with mainstream industrial connectors such as the Phoenix Contact M12, this sensor cable can replace RF coaxial cable to achieve stable signal transmission in environments with strong electromagnetic interference. It is suitable for sensor cabling, industrial networking, and data acquisition applications, offering superior corrosion and interference resistance compared to copper cables.

Name: Industrial-Grade Plastic Fiber Sensor Cable

Model: 1.0/2.2mm-POF (Plastic Optical Fiber)

Product Specifications:

Fiber Type: Step-Index Plastic Fiber

Core Diameter: 1.0 mm

Jacket Diameter: 2.2 mm

Connector: Customizable, compatible with Phoenix Contact M12 connectors

Attenuation: < 0.18 dB/m (650nm wavelength)

Compatible Models:

Can replace RF coaxial cable for signal transmission in specific applications.

Interface compatible with M12 sensor cables from major brands such as Phoenix Contact.

Features:

1. High Flexibility: Small bend radius for easy wiring and installation.

2. Anti-Interference: Completely immune to electromagnetic interference (EMI) and radio frequency interference (RFI).

3. Lightweight and Economical: Lighter and less expensive than glass fiber and coaxial cables.

1.0/2.2mm plastic optical fiber sensor cable is a special cable designed for high-precision sensing monitoring scenarios. It has unique advantages in structural design, sensing performance and application.

Structural design

1. Materials and characteristics: The core diameter is 1.0mm and is made of transparent polymer materials such as high-purity polymethyl methacrylate. This material has a high light refractive index and can effectively guide the transmission of optical signals in the core.

2. Multi-core structure: In the cable with an outer diameter of 2.2mm, multiple 1.0mm fiber cores are arranged in an orderly manner. The specific number of cores can be customized according to different application requirements. The multi-core design enables the cable to transmit multiple sensing signals at the same time, greatly improving the monitoring efficiency and the comprehensiveness of data collection.

Sensing performance

1. Multi-parameter sensing capability

2. High precision and high sensitivity

3. Distributed sensing advantages

Application scenarios

1. Large infrastructure monitoring: bridge monitoring, tunnel monitoring, high-rise building monitoring

2. Energy industry: oil and gas pipeline monitoring, power cable monitoring

3. Industrial production process monitoring: chemical production, machinery manufacturing

4. Security and environmental monitoring: perimeter protection, environmental monitoring