This is a genuine Toshiba TOCP155 CNC industrial-grade fiber optic patch cable, also known as the Toshiba TOCP155 optical cable, designed specifically for industrial control scenarios. Backed by Toshiba quality, it offers high stability, low optical signal transmission loss, and interference resistance, making it resistant to electromagnetic radiation, mechanical vibration, and other complex working conditions found in CNC workshops.

I. Product Overview

The Original Toshiba TOCP155 industrial-grade fiber optic patch cable is a high-reliability optical transmission component designed specifically for CNC systems and industrial automation control. Utilizing genuine Toshiba precision optical components and industrial-grade materials, it offers excellent anti-interference performance, mechanical strength, and signal stability. It is suitable for harsh environments such as vibration, oil, and electromagnetic interference, ensuring error-free high-speed data transmission between industrial equipment.

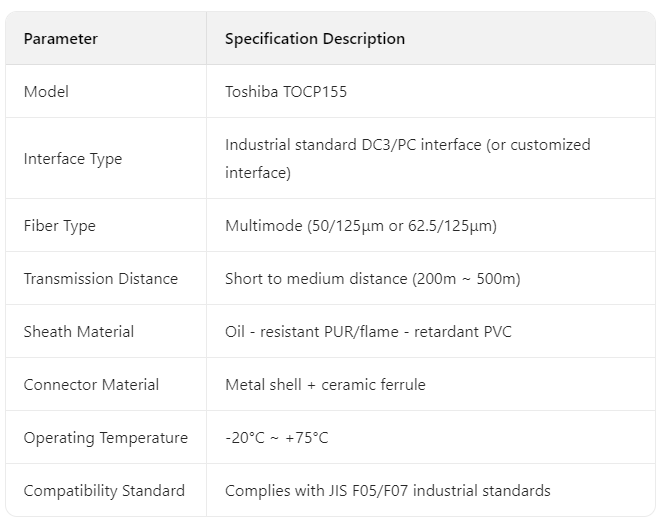

II. Core Specifications

III. Product Features

Industrial-Grade Reliability

The metal connector and oil-resistant jacket provide vibration and shock resistance, making it suitable for harsh workshop environments.

A wide operating temperature range (-20°C to +75°C) ensures stable performance in extreme temperatures.

High-Performance Transmission

Low insertion loss (<0.5dB) and high return loss (>45dB) ensure zero delay and error in control signals.

Completely immune to electromagnetic interference (EMI), it is suitable for high-noise industrial environments.

Plug-and-play compatibility

Perfectly compatible with Toshiba TOCP series devices (such as the TOCP100/TOCP200) and supports leading CNC and PLC brands.

Compliant with JIS F05/F07 standards, it can directly replace older cables.

Long-lasting durability

The ceramic ferrule supports ≥500 plug-in/plug cycles, and the sheath is corrosion-resistant and abrasion-resistant, with a lifespan of over 10 years.

IV. Application Scenarios

CNC machine tools: Optical communication between controllers and servo drives, and I/O modules; Industrial robots: High-speed data exchange between the robot and control cabinet; Factory automation: Connections to PLC networks, sensor networks, and drive equipment; Process control: Signal transmission for high-precision measurement equipment and monitoring systems.