KINZ Optical Fiber Cables can be customized according to customer requirements, including fiber core materials, fiber core quantity, fiber size and length. The fiber core materials have domestic fiber cores and Mitsubishi, Toray, and Asahi Kasei fiber cores. The outer sheath can be customized with domestic outer sheath (more affordable) and imported outer sheath (i.e. 100% imported optical cables).

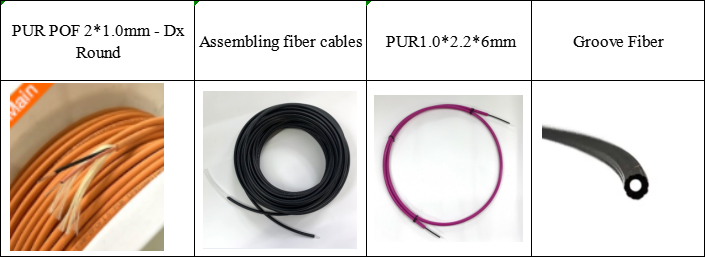

Pictured Models:

PUR POF 2*1.0mm - Dx Round

Assembling fiber cables

PUR1.0*2.2*6mm

Groove Fiber

Product Description:

1. PUR POF 2*1.0mm - Dx Round

Product Overview: This circular duplex plastic optical fiber cable features a PUR (polyurethane) jacket and two 1.0mm PMMA (polymethyl methacrylate) fibers, creating a stable optical transmission architecture.

Applicable Scenarios: Short-distance optical communication scenarios requiring environmental adaptability, such as connecting sensors and controllers on factory production lines in industrial automation control and interconnecting devices within building intelligent systems.

2. PUR 1.02.26mm

Product Overview: This fiber optic cable, with a PUR jacket and a single 1.0mm core and a cross-sectional size of approximately 2.2*6mm, is designed to accommodate specific installation spaces.

Applicable Scenarios: Internal wiring in electronic equipment, such as high-end instruments and precision industrial control equipment, where space constraints and interference-resistant optical transmission are required.

3. Assembling Fiber Cables

Product Overview: Customized fiber optic cables assembled with multiple optical fibers, reinforcements, fillers, and other auxiliary components, tailored to your needs.

Applications: Large-scale fiber optic network construction (such as data center room cabling) and complex optical communication system integration (such as multi-device optical interconnection in smart campuses), meeting batch and customized fiber connection needs.

4. Groove Fiber

Product Overview: Specialized optical fibers with grooves on or within the fiber surface, which enable specific optical transmission control or physical functions.

Applications: High-precision optical communication equipment (such as optical modules and switches), optical sensing systems (such as spectrum analysis and environmental parameter monitoring), and applications requiring specialized optical transmission control or precise fiber optic connection.

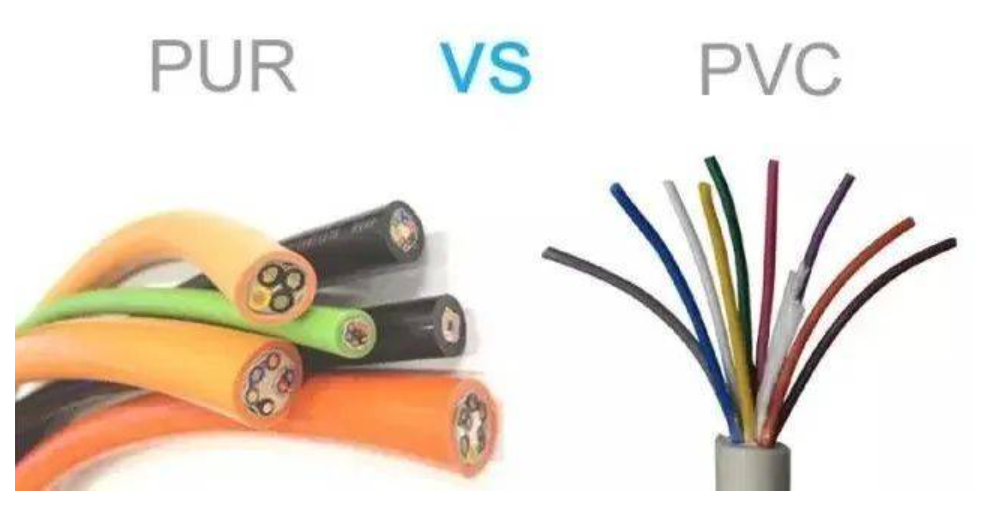

PUR vs. PVC Cable Jackets: Which Is Best for Secure Applications?

When selecting cables for high-security or harsh environments, the jacket material significantly impacts performance. Here’s how polyurethane (PUR) outperforms polyvinyl chloride (PVC) for critical applications like prison systems and industrial automation.

Why PUR Is Ideal for High-Security POF Cables

Tamper-Proof

PUR’s toughness deters vandalism—critical for prison bracelets and secure facilities.

Flame Safety

Unlike PVC, PUR doesn’t propagate flames, meeting strict fire codes for institutional use.

Harsh Environment Survival

Resists moisture, UV exposure, and chemicals (e.g., cleaning agents in prisons).