Two high-performance 1000µm plastic optical fiber jumpers designed for mission-critical environments. The RMPOF1000B is often specified for railway and heavy-duty control applications, while the ST1000-RCPOF1000B offers a versatile ST connector solution for industrial networks. Compare their specifications to select the ideal cable for your needs.

Both the RMPOF1000B and ST1000-RCPOF1000B are industrial fiber optic patch cords made of PMMA fiber with a core diameter of 1000µm. They are widely used in applications requiring high reliability due to their electromagnetic interference resistance, lightweight design, and ease of installation. However, they differ significantly in design and primary application.

Detailed Comparison: RMPOF1000B vs ST1000-RCPOF1000B

1. Connectors and Physical Interface

ST1000-RCPOF1000B:

Connector Type: Equipped with a standard ST connector.

Features: Bayonet-style connection, quick-locking, a very common interface in industrial networks, highly versatile, easy to maintain and replace.

RMPOF1000B:

Connector Type: Typically uses a special connector designed for high-vibration environments (such as models with locking screws or snap-fit mechanisms).

Features: Enhanced connection retention and shock resistance, designed to prevent loosening under severe vibration, meeting the stringent requirements of rolling stock cables.

2. Application Scenarios and Design Positioning

RMPOF1000B:

Main Applications: Designed for core control systems in rolling stock and automotive applications, such as train control and management systems, braking systems, etc.

Design Standards: Complies with stricter industrial and railway standards (such as EN 50155, EN 45545 fire retardancy), suitable for extreme environments.

ST1000-RCPOF1000B:

Main Applications: A general-purpose industrial fiber optic solution suitable for factory automation, internal equipment communication, sensor networks, and some non-critical onboard information systems.

Design Standards: Meets standard industrial-grade requirements, making it a cost-effective choice for building reliable industrial networks.

3. Performance and Environmental Adaptability

Both plastic cables offer excellent durability, but the RMPOF1000B typically delivers superior performance in the following areas:

Vibration and Shock: Higher tolerance level.

Operating Temperature Range: Wider temperature adaptability.

Fire Resistance: Higher flame retardant rating.

How to Choose: Your Selection Guide

Based on the above comparison, your choice should be based on your actual application:

For control systems of high-speed trains, railways, or heavy vehicles?

Choose the RMPOF1000B. Designed for high reliability and safety, it is the preferred choice for rolling stock and control systems.

For factory automation, machine control, or general industrial networks?

Choose the ST1000-RCPOF1000B. Its standard ST connector offers excellent versatility and cost-effectiveness, making it an ideal component for industrial control networks.

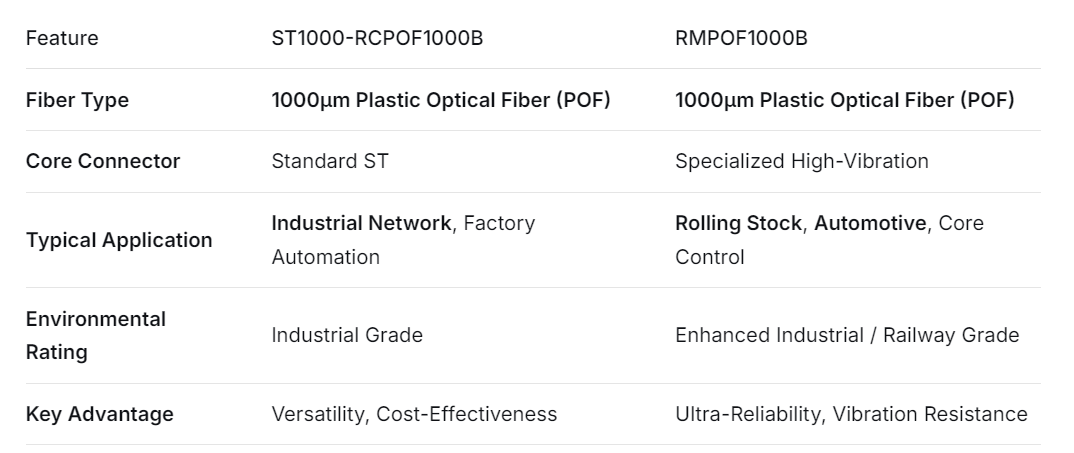

Technical Specifications Summary

Why Choose Our POF Fiber Optic Patch Cords?

As a professional POF jumper cable supplier, our RMPOF1000B and ST1000-RCPOF1000B cables undergo rigorous testing to ensure superior performance. Whether your project involves harsh industrial environments or demanding rail transportation applications, we can provide you with the right 1000µm jumper solution.

[Contact us today for free technical selection support!]